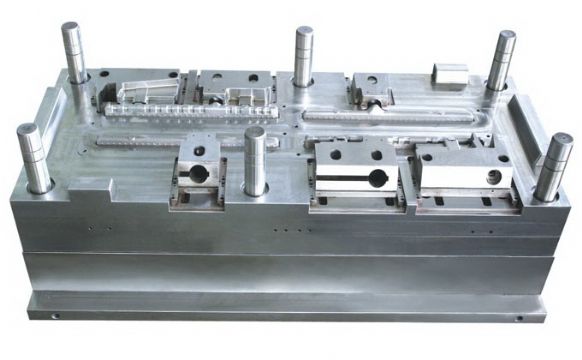

| tooling making

Figure for the automotive rear-view mirror housing, for aesthetics, to streamline the outer surface of the shell surface, shape complexity, other than by the surface composition of the surface, the middle and two holes for mounting the hollow cylinder and multi-root strengthening tendons.

Typically, the injection molded parts of the requirements of uniform thickness. Will lead to uneven thickness of the plastic pieces resulting in stress, warpage, shrinkage and other defects concave. If the thickness is too small, flow resistance when molding large, complex products is difficult to full cavity; if the thickness is too large, too much will not only result in increased costs of materials, plastic molding will increase the cooling time. Use "Tools / Thickness Analysis" command, the thickness of the plastic parts can test, test results shown in Figure

After closing the mold, injection molding machine injection cavity began to ABS, and then after a period of holding pressure molding, injection molding machine with mold after the start with a separate module, to be open to the end position before the mold, the material in the pull rod core role and the role of tight power package, the plastic parts and the flow of condensate is expected to remain in the dynamic model, the pulling mechanism at this time began to drive the hydraulic cylinder under the effect of the lateral side of the slider complete Pulling the top the role of institutions, on plastic parts separated from Slave mode, the reset rod and return spring under the effect of ejector back to the location of the mold is closed, the final mold is closed, bringing the mold to complete a cycle of work.

Mold manufacturers..injection mold china.

Cabin Molds & Plastic Co., Ltd Is engaged in all kinds of plastic mold design, manufacturing, processing, professional business with professional design and development and mold manufacturing division. Have a professional mold manufacturing equipment, superb technology, excellent equipment; adhere to quality-oriented, integrity management, with the majority of enterprises to establish a good relationship. Receiving customer information from a model → → → Create 2D/3D graphics drawings drawing → → confirm → CAD mold on the machine plus / CNC machining / EDM machining mold assembly → → → tryout sample delivery confirmation → A / mass → pay goods, a set of process services to ensure the quality of the mold, to provide you with a more solid guarantee. Processing equipment: CNC milling, engraving, EDM, wire cutting, drilling, grinding, general milling machine, CNC machining center capabilities: mold design, mold manufacturing and injection molding mold material: P20 / 718 / 718H / 2738 / 2316 / S136 / for you to choose, mold: 45 # Pre-hardened> 30hrc cooling system: optimal design of the water cycle, increase productivity, reduce the cost of your mid-term treatment: quenching, post-processing to improve hardness: nitrogen (N treatment temperature low distortion is very small, no longer need to quench it with a high surface hardness (greater than HV850) and wear life: P20 frequently used model is not less than 30 million times a mode of transport: in the mold must be installed before shipment a clamping piece, logistics and transport service: one year mold warranty, free maintenance during the warranty Note: mold in the production process, we have to offer each week and photograph the progress of the mold

Main Market

Western European, North America, Japan & Russia

Payment

T/T,

Packing

For the custom auto plastic accessories: One in a plastic bags tissue paper, then put the bags in a carton

Delivery: By sea or By air

tooling making, mold manufacturers |