injection mold design steps

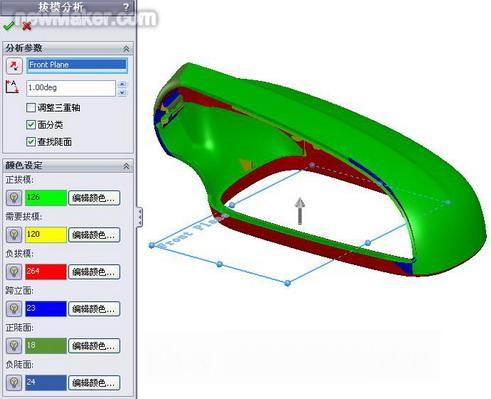

1, the design of the mold product feasibility analysis, computer chassis, for example, the first drawings of each component product group established the use of design software for analysis, said that our work sets of plans to ensure that the mold design prior to the the accuracy of product drawings, on the other components can be familiar with the importance of the entire chassis to determine the key dimensions, so that the mold design is very good, specific sets of plans do not detail the method here described . 2, the product analysis work to be carried out, the product of what kind of mold used to analyze the structure, process and product row to determine the content of the work process red, and the use of software products designed to start in general from the commencement of the product follow-up project started forward, such as a product requirement of five processes, the products of stamping done in product drawings from the beginning to the four projects, three projects, two projects, one project, and launched after a copy of a graphic before then a project to start work, completed five projects that the products of work, and then carry out detailed work, note that this step is very important, and need special care, this is done, the good, the draw will save a lot of time to figure dies , for each project to determine the contents of the press after a good, including the molding, the material thickness of the product lines inside and outside the reservation to determine the size of punch and die used for

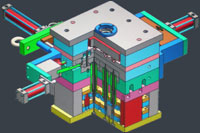

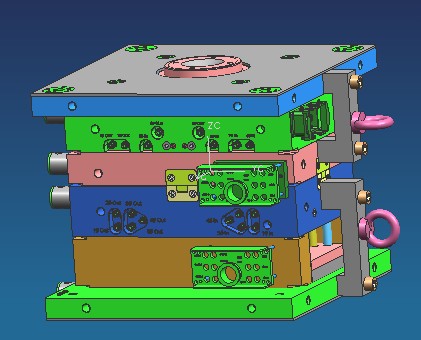

product expansion method described here no longer, will be launched in the product specific method described. 3, preparation, depending on product expansion plan for preparation, in the drawing to determine the size of the template, including the fixed plate, stripper plate, punch and die, inserts, etc., pay attention to the products of the figure directly in the preparation, this figure is on the drawing dies of great benefit, I have seen a lot of mold design products that map directly on to preparation for manual calculation, the efficiency of this method is too low, draw directly on the drawing template Size to set up diagram in the form of expression the one hand, preparation can be done, on the other parts in the mold of the work save a lot of work, because in the drawing of the components work just positioning in preparation to add drawings, pins, guide pin, screw holes can be. 4, the preparation can be entered after completion of mapping of the mold, then the system in the preparation of a drawing out, the drawing of various components, such as adding screw holes, guide pin holes, positioning holes and other holes, and red hole model in a variety of holes to be wire cut through wire holes in the molding, the upper and lower die forming the gap, we must not forget, these after the completion of a product of mold figure has almost completed 80%, and the draw die map process should pay attention: the process, refers to the production, such as bench marking, wire cutting machining process has to wait until a complete different make good layers, so the line cutting and drawing management have great benefits, such as the distinction between

colors, size of the label is also a very important job, but also one of the most troublesome task, because a waste of time. 5, after the completion of the above drawings, in fact, can not issue drawings, drawings of the mold needs to proofread all the parts for assembly, each a different mold plates made of different layers, and the same basis as column-hole until the analysis of the mold set up, and the products of the process map sets up the figure into the group, to ensure consistent and bending template holes position gap with the correct upper and lower mold. injection mold, mold supplier. mold maker |