Injection mold design..

Cabin Molds&Plastic Co,LTD.....Service to customer on injection mold desgin ,Mold flow analysis ,Manufacture

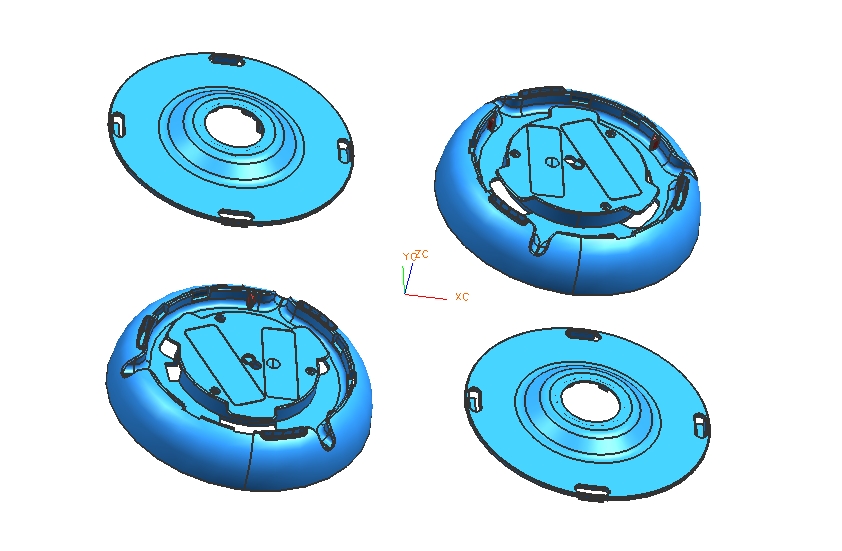

injection mold design for Cabin Molds.

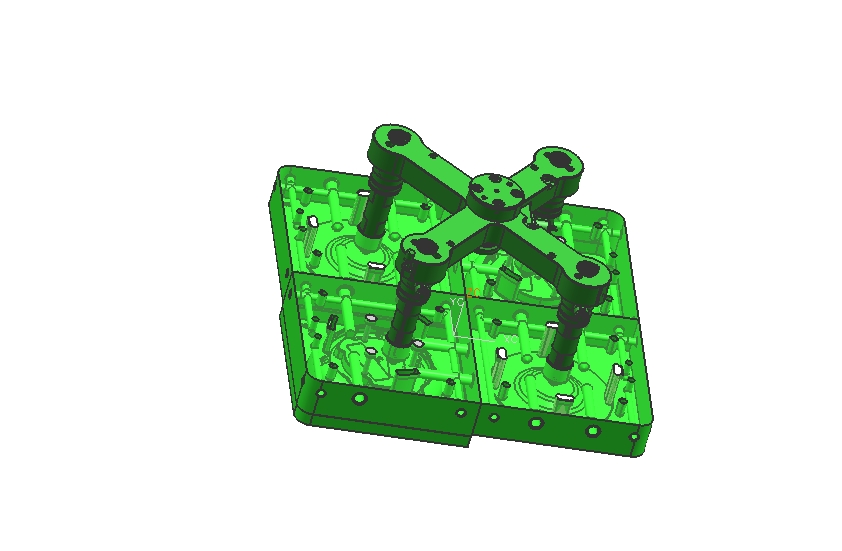

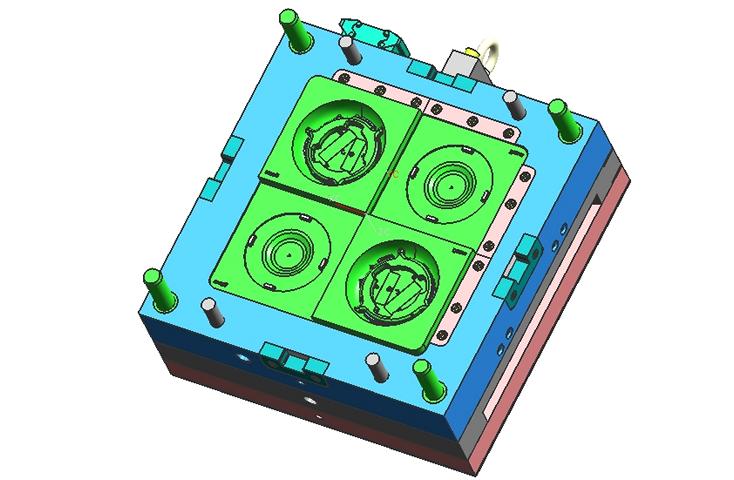

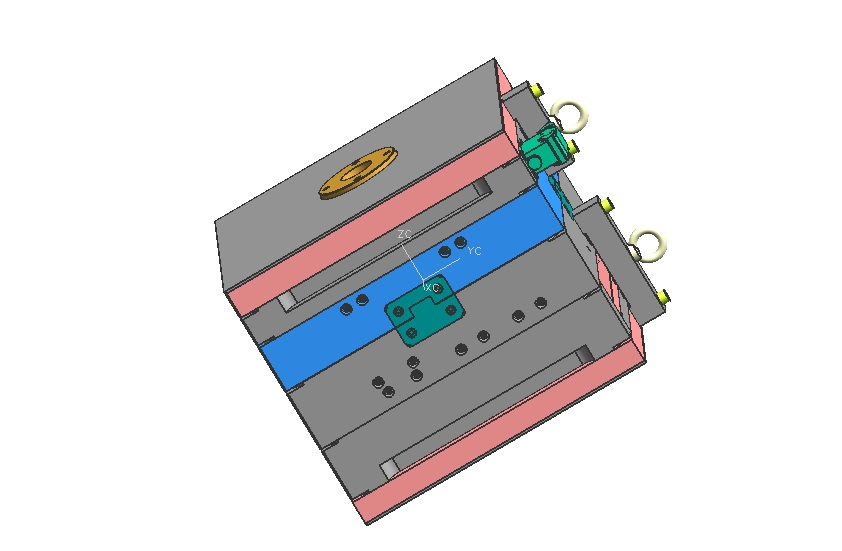

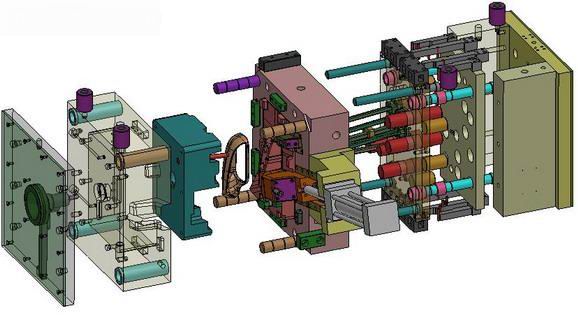

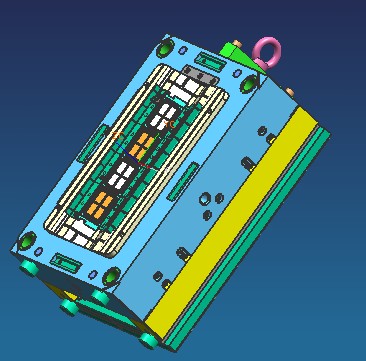

The production Mould Layout The mould hot runner system

The Mould Cavity Side. The Mould Core Side

mold maker, mold manufacturers the mold all side

Cabin Molds&Plastic Co,LTD.....Service to customer on injection mold desgin ,Mold flow analysis ,Manufacture

Cabin Molds&Plastic Co,LTD offer all the mold, The production technical analysis , the Moldflow analysis .the injection mold

need making the deatial 2d, 3d data to Customer confirm it. everything need clearly. after start maching.... the software Format:

AutoCAD, Pro/E ,UG, .....( *.Dxf, *.step, *.x-t.*.capart.)

Doing 3D injection mold design ..Many injection mold factory catched the 3D injection mold engineer not enough doing the work on the busy time...

Our company use below type...

For example have 10 design engineer department..

1.Senior Production and Mold Engineer doing the produce and the injection mold china analysis..

2.Senior 2D mold structure engineeer doing the 2D structure drawing...doing the attention point.

and how to deal with this point..information..

3. 3D injection mold design doing the 3D data. if have problem.. will reflect to prodcution or 2d

Mold design engineer.. find solution.. next ...doing injection mold design next process...

4.Assistant engineer according to the check list ... check the injection mold 3D data.. if not OK the

3D injection mold engineer will optimize the mold data again... next check the 3D injection mold data with the assistant engineer again..

5. if the injeciton mold 3D data OK will sent to Senior Mold engineer check...and confirm it.if

not .will modify...

6. The data ok will sent out to customer confirm it.. after confirm it the tooling shop will start

machining..

7. we are doing injection mold china all process.. will can reduce the time and the cost... Because

if you sent not very good data to customer confirm it. need modify .will lost many time... |