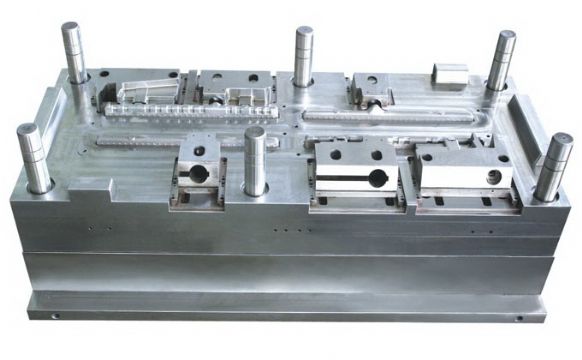

| Cabin Molds & Plastic Co., Ltd Is engaged in all kinds of plastic mold design, manufacturing, processing, professional business with professional design and development and mold manufacturing division. Have a professional mold manufacturing equipment, superb technology, excellent equipment; adhere to quality-oriented, integrity management, with the majority of enterprises to establish a good relationship. Receiving customer information from a model → → → Create 2D/3D graphics drawings drawing → → confirm → CAD mold on the machine plus / CNC machining / EDM machining mold assembly → → → tryout sample delivery confirmation → A / mass → pay goods, a set of process services to ensure the quality of the mold, to provide you with a more solid guarantee. Processing equipment: CNC milling, engraving, EDM, wire cutting, drilling, grinding, general milling machine, CNC machining center capabilities: mold design, mold manufacturing and injection molding mold material: P20 / 718 / 718H / 2738 / 2316 / S136 / for you to choose, mold: 45 # Pre-hardened> 30hrc cooling system: optimal design of the water cycle, increase productivity, reduce the cost of your mid-term treatment: quenching, post-processing to improve hardness: nitrogen (N treatment temperature low distortion is very small, no longer need to quench it with a high surface hardness (greater than HV850) and wear life: P20 frequently used model is not less than 30 million times a mode of transport: in the mold must be installed before shipment a clamping piece, logistics and transport service: one year mold warranty, free maintenance during the warranty Note: mold in the production process, we have to offer each week and photograph the progress of the mold

Main Market

Western European, North America, Japan & Russia

Payment

T/T,

Packing

For the custom auto plastic accessories: One in a plastic bags tissue paper, then put the bags in a carton

Delivery: By sea or By air |