|

Contact us:

Tel: +86-(0)755-36841556

Fax: +86-(0)755-89698547

E mail: Sales@mold-supplier.net

Hcabin@163.com

Skype: wayle123.ning

Tooling shop

CCN shop

Wire Cut Machining

Flat grinding Machining | |

|

moulds ,injection mould china.mold china |

|

mould china/injeciton/make in china

injection mold,mold supplier,mold factory,

tooling shop,tooling maker,mold china.

We are professional for injection mold.

Mold design

1, digital mapping - three-dimensional model of the product and mold into a conventional process using two-dimensional engineering drawings; 2, the number of mold design - based on product model and design intent, the establishment of the relevant three-dimensional solid model mold; 3, die digital analysis and simulation - based on the product forming process conditions, the mold parts of the structural analysis, thermal analysis, fatigue analysis and mold motion analysis; 4, the product forming process simulation - injection molding, metal forming; 5, customized for the company standard parts and mold design standards for the design process; 6, mold production management.

Mold manufacturer

1, bottom processing, processing volume guarantee; 2, the casting is rough looking benchmarks, 2D, 3D surface margin examination; 3,2 D, 3D surface rough, non-installation of non-work surface processing (including security platform surface, buffer mounting surface, flat plate, side datum); 4 and a half before finishing the side plane of the alignment to ensure accuracy; 5, semi-finishing 2D, 3D surface, finishing installation of all types face (including the stopper mounting surface and the contact surface, inserts the mounting surface and rely on the back, punch the mounting surface, waste and by the back of the cutter mounting surface, the spring mounting surface and the contact surface, face all kinds of travel restrictions, wedge and by the back of the mounting surface) , semi-finishing all kinds of guide surface, the pilot hole, the hole left margin finishing technology base and height datum, and record data; 6, test review precision; 7, fitter set for the process; 8, finishing before the process reference datum alignment holes, inserts margin inspection; 9, finishing surface 2D, 3D, red surface and the side holes, finishing holes and the height of the benchmark process benchmarking, pilot hole and guide surface finishing; 10 precision test review

|

Let`t us introduce ourslef below service.

1. Custom the design production .

2. production feasibility analysis

3. Mold flow analysis

4. design injection mold

5. Custom Manufacturing injection mold

6. Prototype Moulds

7. Prototype part

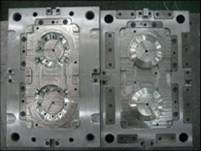

Part name: Automotive Component Mould

Cavities: 1

Mould Steel: P20, S136, NAK80,8407.1.2343. 1.2767. 1.2344, BeCu etc.(for reference).

Mould Base: LKM DME

Mould size: 1500*1800*1201

Weight: 14 Ton

Injection machine: 1800T

Mould Components: MISUMI, HASCO, DME, PUNCH,etc.(For Reference)

Main Softwares: Autocad, UG, PROE, Catia, Solidworks, etc.

After-sales Services: Experienced engineers will provide all-round technical solutions to any problems occurred in customers’ mould operation.

Features: High efficiency, short delivery time, competitive price

Payment

T/T,

Packing

For the custom auto plastic accessories: One in a plastic bags tissue paper, then put the bags in a carton

Delivery: By sea or By air

Delivery time:35~50 day

mold supplier, china injection mold company,china injection mold factory |

|