|

Contact us:

Tel: +86-(0)755-36841556

Fax: +86-(0)755-89698547

E mail: Sales@mold-supplier.net

Hcabin@163.com

Skype: wayle123.ning

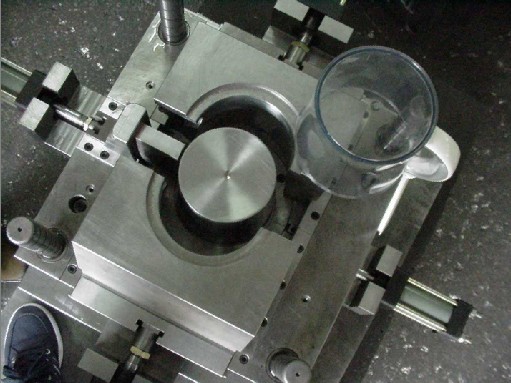

Tooling shop

CCN shop

Wire Cut Machining

Flat grinding Machining | |

|

injection mold china,Silicone mold methods |

|

injection mold china with cabin Molds&plastic Co.,ltd

Silicone mold methods of operation:

1 silicone mold and the curing agent stir the appearance of the silicone mold the flow of liquid, A is a silicone component, B component is a curing agent, for example: take 100 grams silica gel, add 2 grams curing agent (Note: silicone and curing agent be sure to stir, if not stir, the mold will be dry and cure the condition of uneven impact of silicone molds, and molds the life times, and even cause mold scrapped.

2 rows of bubbles vacuum treatment: silicone and the curing agent stir row of bubbles after the vacuum part of the time the vacuum should not be too long, not more than 10 minutes, or silicone curing cross-linking reaction can not be brushing or pouring, resulting in material waste.

3 brushing operation: the row over the silicone bubble: the way to brushing or pouring down on the master mold (mold or infusion in the brush before playing the mother mold release agent or mold release agents) must be uniform brush mode, 30 minutes after the sticky layer of gauze or glass fiber cloth to increase the strength of the mold and pull, making brushing and then paste the second layer of gauze or glass fiber cloth, then silicone brush, after such treatment out of the mold with life and molds more times, long life, cost savings and improve efficiency.

4 modes of production outside the general approach is to die surrounded by a plastic sheet or wooden floor, a box is filled with plaster to mold can be, and the other outside the mold resin is used the way brushing brushing brushing a layer of resin, glass fiber cloth and then brushing a layer of paste and then repeated two three can be completed outside the mold.

5. Silicone (silicone, silicone) and curing agent ratio to reflect the situation: It is recommended curing agent added can not exceed 5%, the greater the percentage of curing agent added, the faster cure time, mold the more brittle, short life. Also based on the amount of product and process requirements better by adding silicone molding, silicone oil should not be too much attention (5% -10%), or affect the tensile and hardness silicone mold.

Silicone molds Note:

1, B component is a catalyst, vulnerable to tidal solution, it should be used after the reclosable lid.

2, A, B group have been mixed, a chemical reaction; immediately, a gradual increase in viscosity, can not stop, in order to avoid waste, should be based on the amount of use with the distribution, with a good should be used immediately, without delay.

3, A, B group, with the ratio, related to the chemical reaction speed and mold performance. Group B were more, the faster the reaction, products of higher strength and hardness, but the toughness decreases. Therefore, accurate weighing requirements.

4, the preparation done, the A group were expected to stir up and down, and then weighed.

5, the casting method is suitable for class relief, brushing method for the production of three-dimensional mold. Die casting class relief should be made larger than the original length and width are carving wide, and standing 4-6CM border. Border to ping, to smooth inner surface. When pouring place a border on a clean glass, and then the original in the box, leaving each side of the gap 2-3CM. (25-35 silicone mold of $ / KG)

Silicone mold-making process in the bubble solution:

1, improved flash tank and exhaust system design

2, increasing the pressure of press

3, to reduce the amount of release agent, and spray evenly

4, material control water ........

5, can try to add some defoamer

6, the use of cold runner.

7, vacuum pumping with a vacuum machine, the mold can increase the exhaust operation.

|

We are professional on injection mold , Plastic part, Silicone mold

we are provide below service . if you need below service .Please contact us any time

1. Custom the design production

2 Production feasibility analysis with the mould

3 Mold flow analysis

4 design injection mold

5 Custom Manufacturing injection mold

6 Prototype Moulds

7 Prototype part

Main Market

Western European, North America, Japan & Russia

Payment

T/T,

Packing

For the custom auto plastic accessories: One in a plastic bags tissue paper, then put the bags in a carton

Delivery: By sea or By air

Delivery time:25~35 day

|

|