|

Contact us:

Tel: +86-(0)755-36841556

Fax: +86-(0)755-89698547

E mail: Sales@mold-supplier.net

Hcabin@163.com

Skype: wayle123.ning

Tooling shop

CCN shop

Wire Cut Machining

Flat grinding Machining | |

|

mold in china, mold china |

|

mold in china, mold china.

mold supplier,mold manufacturer.

mold design china

Mold mold surface polishing technology is an important part of engineering, mold manufacturing process is an important process in the post-processing. At present, polished to ra0.05μm mold polishing equipment, grinding and abrasive processes, you can basically meet the need, but to throw to ra0.025μm mirror polishing equipment, grinding and abrasive processes is still in the exploratory stage. With the mirror injection mold of large-scale applications in production, mold production mold polishing technology has become a key issue. As the domestic polishing technology and materials, there are still some problems, so the camera lens as a fool injection mold, cd, vcd discs and tools for high transparency, a large part of the injection mold is still dependent on imports. Luobai Hui said that the mold surface polishing equipment and polishing process is not affected by the impact of technology, but also by the degree of the impact of the mirror mold material, which has not attracted enough attention, that is, polishing itself constrained by the mold material. For example, do 45 # carbon steel injection mold, polished to ra0.2μm, the obvious visible defects, to continue throwing to only increase the brightness, while the roughness has no hope of improving it is the current domestic production of mold in the mirror tend to use imported mold material, such as Sweden ASSAB 136, Japan harmony pd555 other mirror can be satisfactory degree.

1, personnel streamlining,

"Thin" type management. Most small businesses die in Europe and America, the number of employees less than 100 people, the number of mold companies are generally 20 to 50 people. Various categories of staffing is very thin, multi-skill, more than one job, do not see the internal idlers. Lean production, "thin" type management ideas are better reflected.

2, the use of specialized, product positioning accurate. Luo Baihui the mold inspection companies, mostly around the automobile and electronics industries, the demand for all types of mold, determine their own product positioning and market positioning. In order to survive in market competition, development and each factory has its own advantages mold technology and products, and have adopted specialized methods of production. Most of the existing number of European and American companies long-term mold mold user, a group of large companies around the mold collaboration mold manufacturers. This reciprocity, mutual benefit, win-win, co-partnership, and some have lasted 30 to 40 years.

3, the use of advanced management information system to achieve integrated management. European mold enterprises, especially large-scale mold companies, and virtually computer management. From production planning, process development, to quality control, inventory, statistics, the widespread use of computers, various departments within the company can share information through computer networks.

4, process management of advanced, high degree of standardization. Most of the domestic adoption of a mold factory fitter fitter-based or lump sum of different modes of production organization, Europe and mold manufacturers are relying on advanced technology and routing equipment to ensure part accuracy and production schedules. Per mold are detailed design, including the detailed design of each part, and have developed a detailed processing.

|

|

mold in china, mold china.

mold supplier,mold manufacturer.

mold design china

molding in china, molding china, injection molding china ,mold in china. mold design china

mold in china, injection mould china

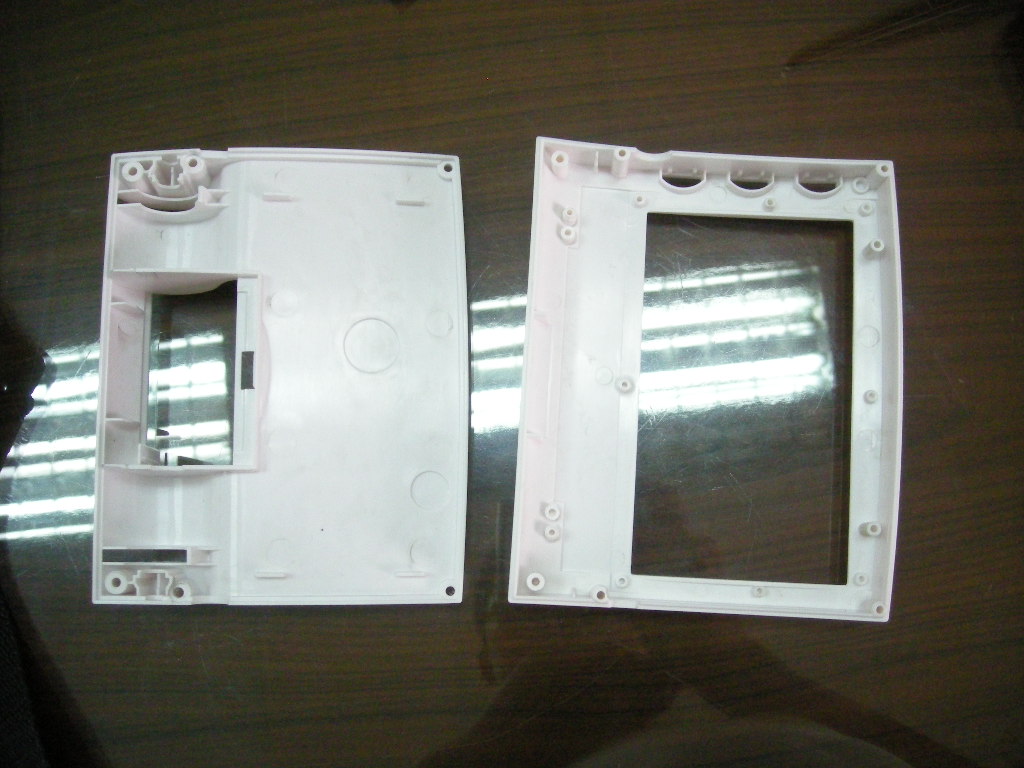

these we are some telephone display samples. we are offer the plastic samples service it

we are offer the high quality plastic samples and injection mold. and the low price it

china injection mold company/2k mold/ mold supplier/ mold factory.

injection moldmaker mold maker plastic part

|

|