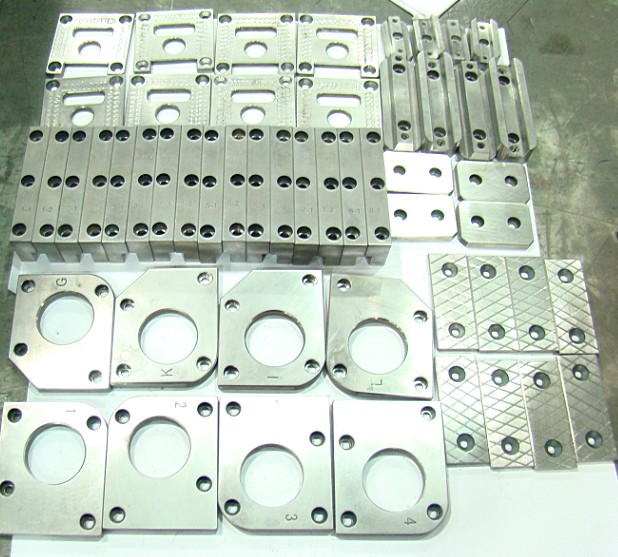

Part name: injection mould - Automotive Component Mould-Plastic mould

Cavities: 1

Mould Steel: P20, S136, 718,718H,738, 738H, 1.2344, 1.2767 BeCu etc.(for reference).

Mould Base: LKM. Hasco Standard

Mould size: 1100*1500*1351

Weight: 14 Ton

Injection machine: 1300T

Mould Components: MISUMI, HASCO, DME, PUNCH,etc.(For Reference)

Main Softwares: Autocad, UG, PROE, Catia, Solidworks, etc.

After-sales Services: Experienced engineers will provide all-round technical solutions to any problems occurred in customers’ mould operation.

Features: High efficiency, short delivery time, competitive price.

injection,Plastic mold,mould,injection mould

mould chian,mold china design,mold china mold flow

Plastic mold maintenance is always reflected in the production, not only in shape after the maintenance. Plastic mold when the mold is loaded needs some maintenance. It refers to the production of plastic molds for the operator and daily maintenance, mainly for clearing brush, lubrication and inspection.

Die before the upper and lower surfaces of the plastic mold and clear brush, plastic mold mounting surface to ensure that the work surface and press against the production of crushed and die down in the mounting surface parallelism.

Plastic mold auto mold will be installed to open, to distinguish between the plastic mold clean ministries, especially the guiding mechanism for the surface of the pieces of plastic mold, clean the surface clean to ensure the quality of parts. The sliding section of the plastic mold copies for lubrication, coating grease, plastic mold of the part of the inspection, especially the line position, slant, cylinder, ejector plates, road and other waste.

|