Plastic injection mold flow

Mold is first of all manufacturing to accelerate skills-based training, can not do without the cultivation of the mold. CNC Machining technology must first have advanced machine tools and processes, followed by more people have a good mold - mold technician to guarantee; mold CNC machining technology is embodied in the mold design and mold operation, the quality and precision molds, also rely on advanced machine tools, technology and excellent technicians to ensure that mold. In advanced countries, mold making has been the implementation of "paperless", die by the computer division to design, computer processing is to input data for mold development. Then advanced CNC machine tools, there is no good people die, no long-term skills training, is not in operation

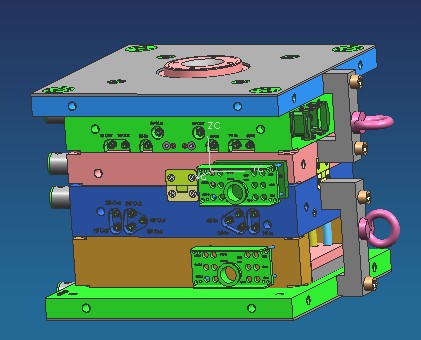

Part name: Automotive Component Mould

Cavities: 2

ould Steel: P20, S136, NAK80,8407.1.2343. 1.2767. 1.2344, BeCu etc.(for reference).

Mould Base: LKM DME

Mould size: 1500*1800*1201

Weight: 14 Ton

Injection machine: 1800T

Mould Components: MISUMI, HASCO, DME, PUNCH,etc.(For Reference)

Main Softwares: Autocad, UG, PROE, Catia, Solidworks, etc.

After-sales Services: Experienced engineers will provide all-round technical solutions to any problems occurred in customers’ mould operation.

Features: High efficiency, short delivery time, competitive price

Payment

T/T,

Packing

For the custom auto plastic accessories: One in a plastic bags tissue paper, then put the bags in a carton

Delivery: By sea or By air

Delivery time:35~50 day

we are making mold in china ,plastic injeciton,mould,mold,good samples

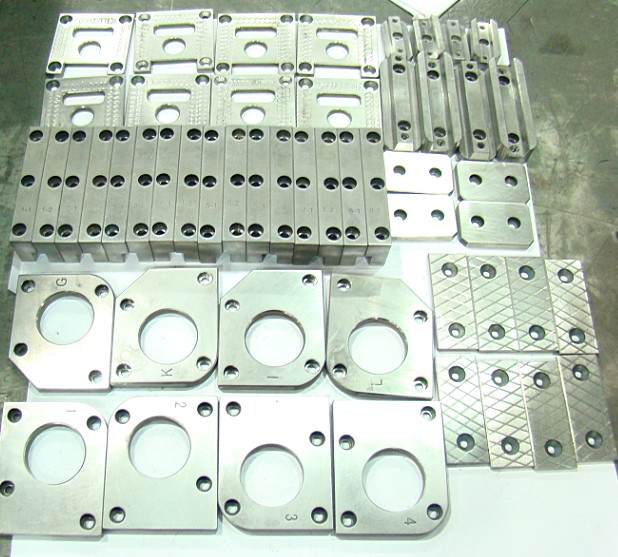

Mold machining , Mold surface processing technology,with CNC

programming and machining EDM tooling ,molding process,a typical part of the

mold,the mold surface finishing and mold assembly

|